In 2023, Duke Energy will complete an upgrade at its Bad Creek Hydro Station in Salem, South Carolina. Upon completion, the station will have a capacity rating of approximately 1,640 MW — making it one of the largest pumped storage hydro stations in the United States.

By choosing to upgrade the units, rather than performing major maintenance, Duke Energy is gaining an increase in capacity equivalent to an entire additional generating unit.

When a facility such as Bad Creek reaches a major maintenance milestone, the incremental cost of upgrading the units compared to maintenance costs is an economical alternative to add new carbon-free generation to the electrical grid. Advancements in hydraulic design can be employed to increase the capacity of existing units without building new dams, reservoirs, or powerhouses.

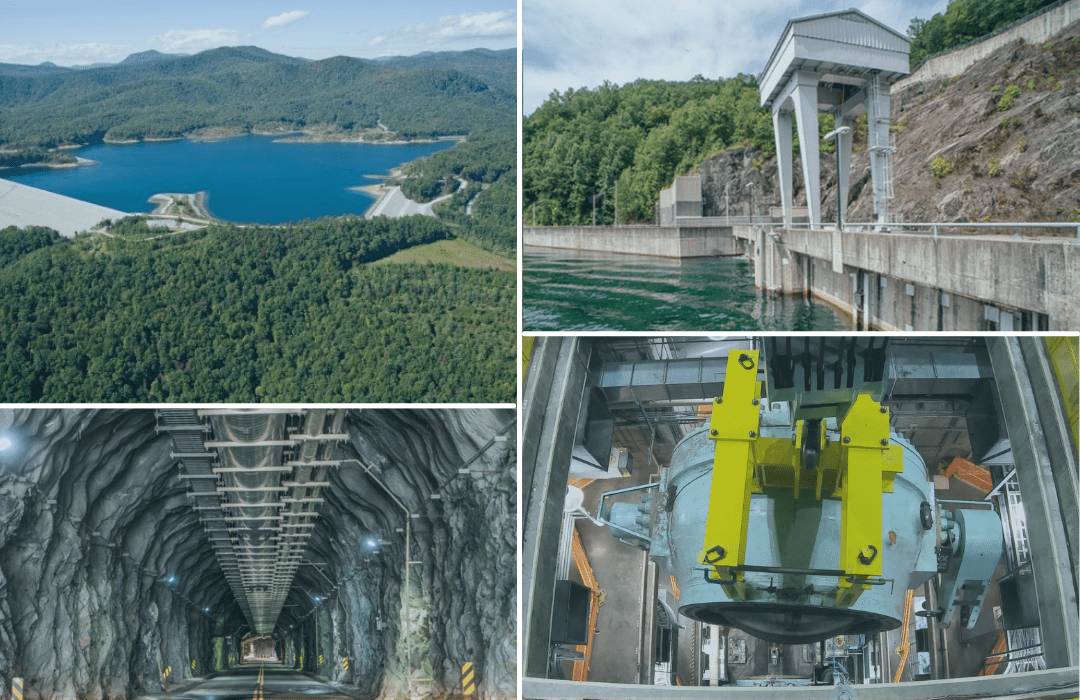

Bad Creek Reservoir – Bad Creek, which came online in 1991, is Duke Energy’s youngest hydro plant. Its construction took roughly 10 years and cost $1 billion – it was finished one year ahead of schedule and $90 million under budget.

Duke Energy’s incremental budgetary estimates to perform the upgrade instead of major maintenance at Bad Creek was the most economical new capacity option available to the utility. The fact that the additional 280 MW is renewable is a major bonus.

WHY IT MATTERS

Bad Creek is essentially the company’s largest battery. With fast-growing solar power that ebbs and flows depending on cloudiness, time of day and other factors, pumped storage is the perfect partner because it’s reliable and flexible.

This additional capacity and storage help balance our nuclear generation and other renewables. It also enhances our ability to produce power during periods of high demand.

This is the largest power uprate at a Duke Energy hydro plant. A similar turbine uprate was completed at Duke Energy’s Jocassee Hydro station in 2007 and 2011, which improved the capability of that site to store and convert electricity. At Jocassee, each unit reflected a 25-MW upgrade, or 100 MW combined.

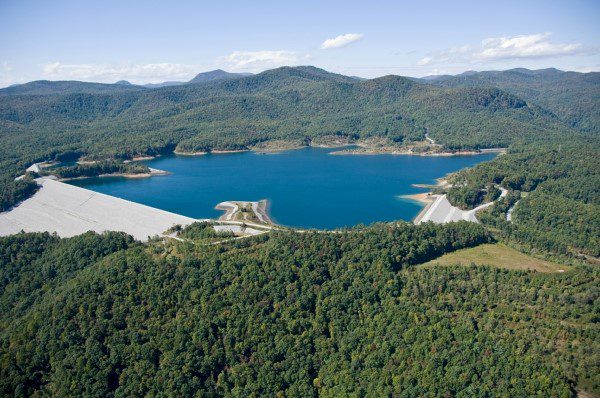

Station tailrace at Lake Jocassee

As pumped storage and conventional hydro facilities reach major maintenance windows, a similar analysis and project is likely feasible with the incremental cost difference between the normal maintenance and the upgrade. This incremental investment is an economical way to add renewable generation to the portfolio or fleet in question.

SCOPE OF WORK AND TIMELINE

As part of Duke Energy’s strategy to increase renewable energy, upgrades to the plant will add approximately 280 MW to the pumped-storage hydro station. Its comparable output will produce as much electricity as Duke Energy’s other large generating stations in the nuclear and fossil fuel fleet and power more than 1 million homes.

In 2018, the Federal Energy Regulatory Commission approved a non-capacity license amendment to allow Duke Energy to add generation capacity to Bad Creek, located about 140 miles southwest of Charlotte.

The new, more efficient and powerful pump turbines reflect advancements in turbine design and computer-based modelling capabilities.

The work to add capacity includes installing:

- Four more efficient and powerful pump turbines

- Three new higher-rated generator step-up transformers

- New higher-rated generator output circuit breakers

The scope of work also includes upgrading the generator stators, refurbishing rotor poles, replacing generator rotor rim iron and refurbishing spherical valves.

The increases in power will be phased in as each new pump-turbine unit comes online. In October 2020, Bad Creek Hydro completed the first of four unit uprates, with Unit 2 commissioned to provide an additional 70 MW of generating capacity. (The overhauled pump-turbine unit generator output increased from 340 MW to 410 MW; pump load increased from 310 MW to 375 MW.)

The uprate on Unit 1 was completed in September 2021. Just like with Unit 2, the same additional capacity and regulation band was achieved with the Unit 1 upgrade.

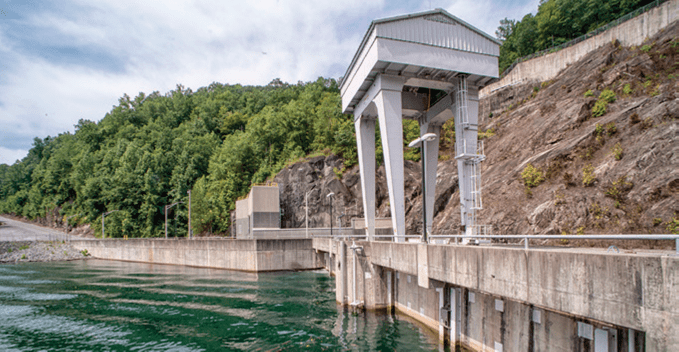

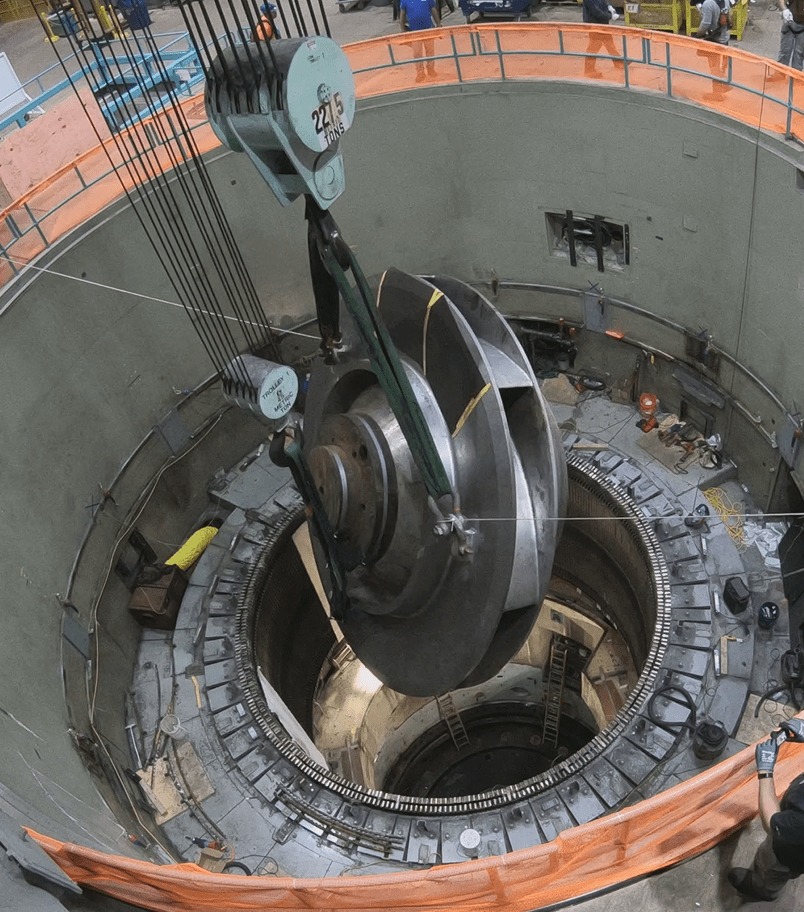

This photo shows removal of the original pump turbine runner from Bad Creek Unit 2.

Uprate work on Unit 3 is in progress and Unit 4 will start its upgrade in October 2022. All four units will be upgraded and the projects will complete in the summer of 2023.

FAST FACTS ABOUT BAD CREEK

Conceptual design of the Bad Creek project began in the 1970s and the Federal Energy Regulatory Commission license was issued in 1977.

The original turbines were designed in the 1980s and the plant came online in 1991, with four generating units and a station capacity of 1,360 MW.

Project features:

- Length of main dam: 2,600 feet

- Full pond elevation: 2,310 feet above mean sea level

- Upper reservoir: 318 acres at full pond

- Powerhouse cavern: 75 feet wide, 164 feet high, 433 feet long

- Discharge tunnels: 1,200 feet long

- Total project site: 1,600 acres

Upgrades reflect advances in technology

The fundamental building block of the upgrades is the pump-turbine. Voith Hydro designed a pump-turbine with eight vanes instead of seven, while optimizing the design for less cavitation. New turbine shafts are also being provided to handle the additional torque from steady-state and transient conditions.

Enhanced environmental mitigations, such as greaseless bushings for the wicket gates, are also being employed to help protect the pristine lakes in upstate South Carolina.

With the additional mechanical power of the pump-turbine, the generator motor for each unit also has to be rebuilt within the same geometrical constraints as the original equipment. Andritz designed and is completely rebuilding the rotor rim and stator core, rewinding the stator and doubling the number of generator cooling fans for each of the four units to seize the added potential of the pump-turbine uprate.

In the process, Andritz is also refurbishing the field poles to resolve an insulation migration problem with the existing poles.

Increasing the generator output and motor load required more capable unit circuit breakers. The previous ABB breakers were air blast style breakers that did not suit the increased frequency of unit cycling that has become the new normal for pump storage as non-dispatchable renewables continue to be built. The new breakers provided by ABB are SF6 breakers designed with breaker monitors that extend the life of the chambers by using Zero crossing logic to minimize arching during breaker operation. These monitors also perform other online calculation functions to help schedule maintenance based on condition rather than time, which optimizes operations and maintenance expenditures.

All four Bad Creek generator circuit breakers were upgraded from air blast design to SF6 to handle the additional capability and increased cycling of the units.

With the generators 800 feet below ground and step-up transformers above ground, keeping the 19KV isolated phase bus (IPB) cool is critical. With the additional current flow in the IPB, significant cooling capacity had to be added to the IPB duct cooling system. AZZ Calvert and HDR Engineering designed an IPB duct cooling system that inserted duct bushings to isolate the cooling zones of the IPB duct, changed design cooling air flow directions, and added cooling fan capacity to service each zone. Outside air chillers were also designed and added to chill water flowing to the heat exchangers so that the air flowing through the IPB duct is adequately cooled after picking up heat in the earlier phases of the duct.

Finally, with the higher capacity of the station, the generator step-up (GSU) transformers had to be replaced. ABB designed, manufactured and installed three new GSUs for Bad Creek. At the time, these were the largest transformers ABB had manufactured, so ABB had to enlarge the winding tables in its factory to manufacture these transformers.

Hydro, renewables key to clean energy transformation

By 2050, Duke Energy plans to achieve net-zero carbon emissions from electricity generation. In 2020, the company also accelerated its goal for cutting emissions by 2030 from 40 percent (one of the industry’s most ambitious) to at least 50 percent. Since 2005, the company has lowered its carbon emissions by more than 40%, accelerated the timeline to retire coal plants and expanded its renewables portfolio.

While some technologies necessary to achieve this goal are not yet available, Bad Creek and Jocassee will be able to support the integration of these various energy sources regardless of their intermittent nature.

The company is also evaluating new pumped-storage and battery storage as part of various potential scenarios to provide increasingly clean, reliable, renewable and affordable energy to its customers.